Previously we have looked at how the power output of a turbine depends on different factors such as wind speed and power-coefficient. Feel free to jump back if you need a refresher.

Let us try to use it in practice. We will take a Siemens Gamesa 11MW Turbine as an example.

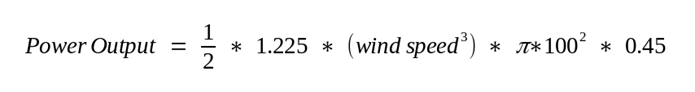

- As mentioned before, 1.225 kg/m3 is a good baseline value for air density.

- This turbine has a blade radius of 100 m, so the rotor swept area is given by π*1002.

- While the power-coefficient is not a fixed value and changes over time, let us assume that it is fixed for this example. We will assume this turbine can operate at a fixed power coefficient of 0.45 - or roughly 75% of the Betz Limit.

That gives us the following formula for the power output:

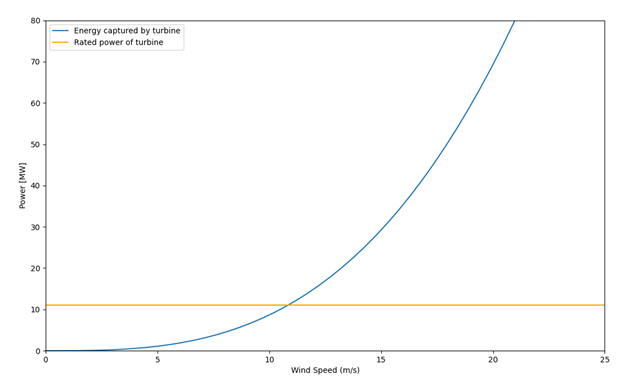

Let us plot the wind speed here against the rated capacity of the turbine:

As you can see, the increase in wind speed dramatically increases the power output of the turbine. However, all turbines have a rated power capacity – which is the maximum amount of power it can produce.

Let us look at the interactions between the wind speeds and the different ways a turbine can operate.

Cut-In and Cut-Out Speeds

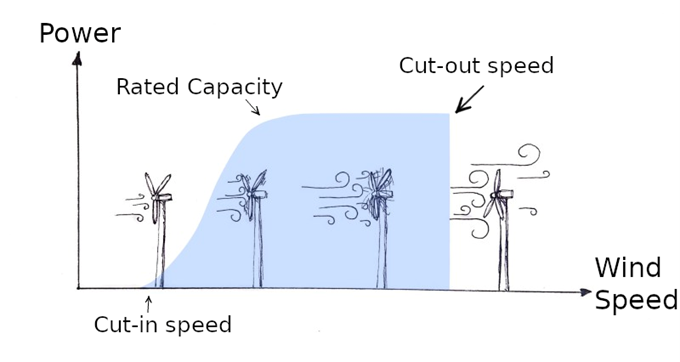

So, what happens when the wind speed is too slow or too fast? There are a few stages a turbine can operate in, depending on the wind speed.

The blue curve explains how much power the turbine generates at different wind speeds.

Low Wind Speeds – The Turbine Is Idling

At low enough wind speeds the wind speed is not enough for the turbine to rotate. The turbine will generally consume power from the grid at this stage, to keep all the systems running.

Cut-In Speed – The turbine starts to rotate

At some point the wind speed will be high enough that the turbine can generate power. This speed where the turbine will start to rotate is the cut-in speed.

The cut-in speed is often around 3-4 m/s but varies from turbine to turbine. For many turbines, extra electricity is used, to quickly get the rotor spinning when the wind reaches the cut-in speed. The goal here is to extract as much power from the wind as possible.

Rated Power Production

As the wind speed increases, the energy output of the turbine also increases, until it reaches its rated power. Here the goal goes from “Capture as much power as possible”, to “Capture the power the turbine is rated for” - if the wind speed increases, the turbine will generally pitch its blades to capture less energy than is in the wind.

For the Siemens Gamesa turbine above, the turbine will start pitching out when reaching the 11MW power production. At this point the power output of the turbine will be approximately constant, even if the wind speed keeps increasing.

Cut-Out speed – The Turbine stops

If the wind speed keeps increasing, it might reach the Cut-out speed. The cut-out speed is the wind speed where the wind is so powerful that it is no longer deemed safe for the turbine to operate under the strain that the wind puts on it. The turbine will feather its blades, meaning that they will turn them to be parallel to the air – thus not capturing any wind power.

Operating a turbine is tricky business, and there are many details and a lot of depth in a subject like this. Here we have mentioned some of the overarching principles. As you can see operating turbines is vastly more complex than simply pointing them at the wind – there are many moving parts and control systems in a turbine.

Written by Gustav Wengel, Software Engineer at SCADA MINDS.

Read more on Gustav's code adventures here.